Medical Device Design & Development Innovative Processes, Reliable Outcomes.

Design & Development

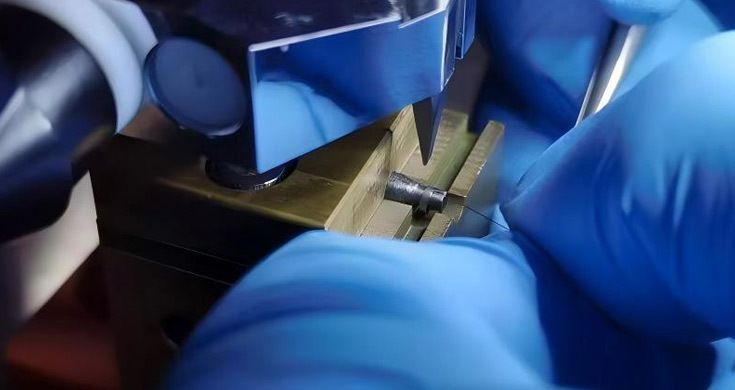

We are involved in the design and development of medical devices. Our team follows a multi-stage design process to provide the best products for our clients. This proven approach helps structure the product development workflow and ensures maximum collaboration at every stage. Throughout the process, we maintain regular communication with our clients, providing consistent and timely production schedules while thoroughly documenting each step of the development.

We utilize the latest tools and technologies to co-develop groundbreaking medical device designs, creating robust, safe, effective, and budget-friendly products. We develop manufacturing processes that ensure efficiency throughout the entire product lifecycle, from launch to market introduction. We also validate the entire product development process—from bottom-up creation to parallel line transfer.

Design for manufacturing

The products we produce go through a strict quality control process, and can be delivered in a timely manner without defects. The capabilities we provide in the reliability/manufacturability design phase include:

1. Early involvement of process and manufacturing engineers;

2. Perfect design and transfer internal procedures;

3. Early contact with customers and supply chains;

4. Cross-functional review of manufacturing processes;

5. Equipment selection;

6. Lean methods and lean tools, such as 3P;

7. Statistical data analysis;

8. Process appraisal begins before certification;

9. For complex catheters - make use of in-house capital equipment and previously developed process experience

Product Development

Diagsensor Medical has deep experience developing and manufacturing complex catheter and medical device systems for demanding applications. We offer a breadth of product development capabilities that encompass everything from refinement of concepts and processes to test method development and design verification:

Product Development and Process Development:

Concept refinement

Iterative loop testing and prototyping

Design confirmation

Design freeze/testing and documentation

Design Verification

Characterization testing

Engineering analyses (DOE, tolerance analyses, FEA, etc.)

Review of historical data

Design confirmation testing

Product performance testing

Biocompatibility testing

Accelerated aging shelf-life testing

Real-time shelf-life testing

Packaging verification testing

Test Method Development

FEA

Reliability testing

Limit testing

Limited conditioning (humidity, temperature, etc.)

Bubble emission package testing

Tray/pouch seal testing

Ex-vivo testing

Sterilization validation

Material biocompatibility testing

Dye penetrant package testing

Full package conditioning/ship testing/aging

Surface analysis

SEM material analysis

Concept and Prototype Design

By combining experienced engineering resources with human factors and industrial design expertise, Diagsensor Medical is in a unique position to assist you through your concept development. Our world class ideation and prototyping capabilities include:

Voice of the Customer Research

Storyboarding and Communication Tool Development

Authoring the Problem Statement

Concept Development and Selection

Bench Top Test Models

Rapid Prototyping

Medical device concept design and evaluation

Complex Parts Design (Solidworks)

Complete conduit delivery system

Handle and mechanism design

Drawing package development and design documentation

Structured stage gate development process

Manufacturing fixture design and documentation

Complete transfer of product intellectual property rights

Design validation, validation and pre-production

Initiate the transition from R&D to commercial production

Mass production

Medical device development services

Minimally invasive treatment and diagnostic medical products for:

electrophysiology

Peripheral blood vessel

Interventional cardiology

Interventional pulmonology

One-time use endoscopy/gastroenterology

Development of pipe guide manufacturing process

Supply chain selection, management and technical oversight

Development, implementation and reporting of in vivo study protocols