Lean Manufacture

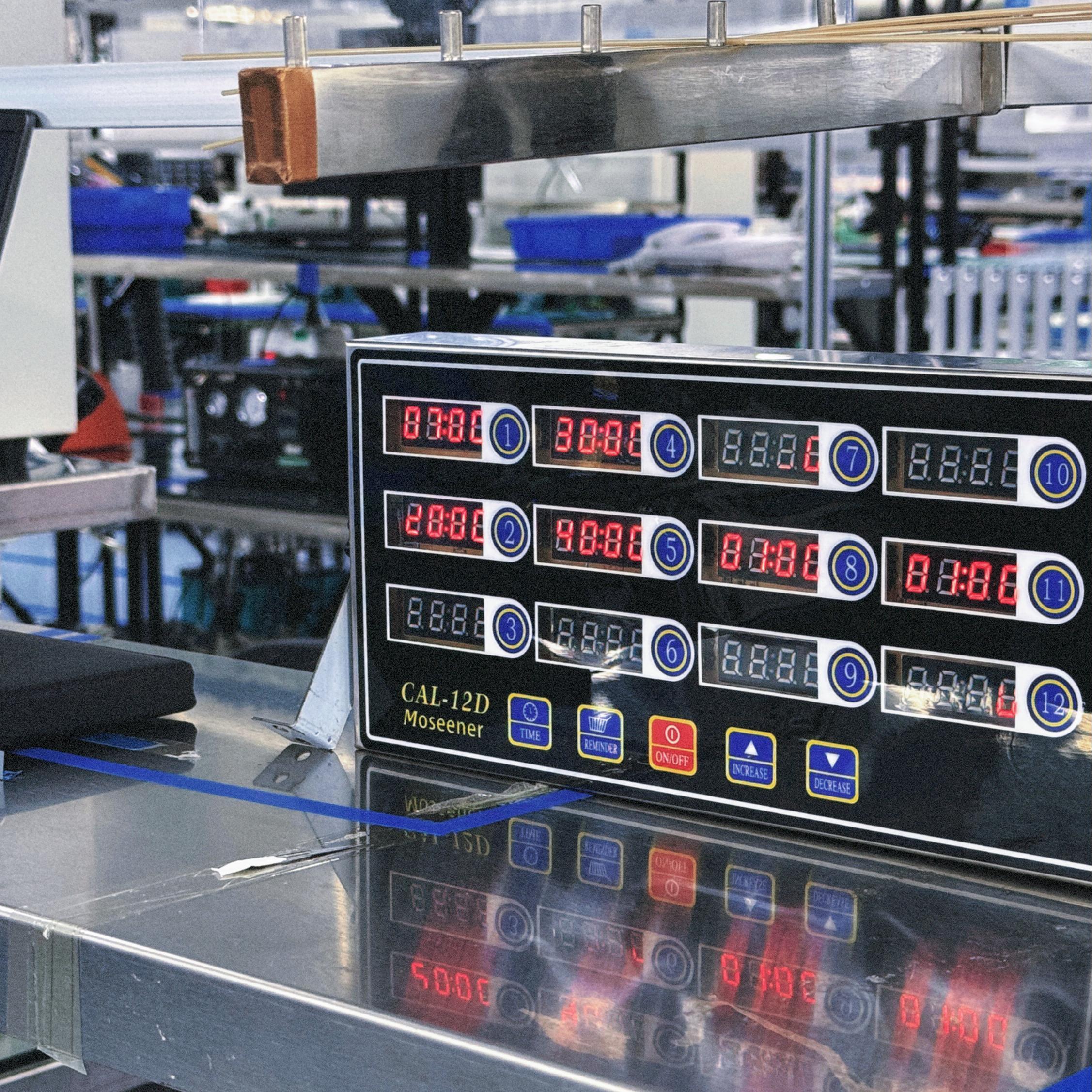

Diagsensor Medical has multiple platform technologies for the manufacturing of interventional devices. Additionally, its team has experience in the development of automated and semi-automated equipment, which improves production efficiency and reduces costs, enhancing the market competitiveness of clients' products. In terms of soft skills, Diagsensor Medical's core team has many years of experience in the development and manufacturing of high-precision micro-interventional active medical devices. To address the challenges of assembling micro-high-precision components and the long training periods for employees, a scientific training system has been established to ensure both production efficiency and product quality.

The core team members have over 10 years of experience in active interventional medical devices, with expertise in large-scale manufacturing of complex, high-precision products, producing over a million units annually. We focus on lean production and continuous efficiency improvement, along with the development and application of automation equipment.

When you partner with us, you will find that our philosophy is embedded throughout the organization, from understanding customer needs to delivering the final product. We work closely with clients to define processes and procedures that shorten delivery times, create balanced workflows, meet requirements, and achieve excellence in quality.

这里是占位文字

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容

这里是占位文字

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容

这里是占位文字

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容

这里是占位文字

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容

We use patents, proprietary processes, methods, and data systems to assess manufacturing processes and locations to optimize performance.

Global communication planning enhances quality and efficiency throughout the entire product lifecycle.

Our integrated global project teams include experts in management, engineering, finance, regulatory affairs, and manufacturing.