Drive micro-manufacturing to excellence!

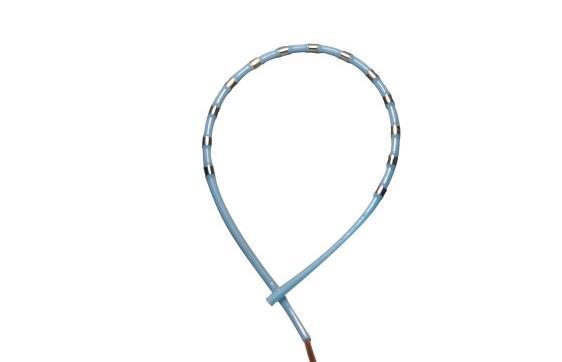

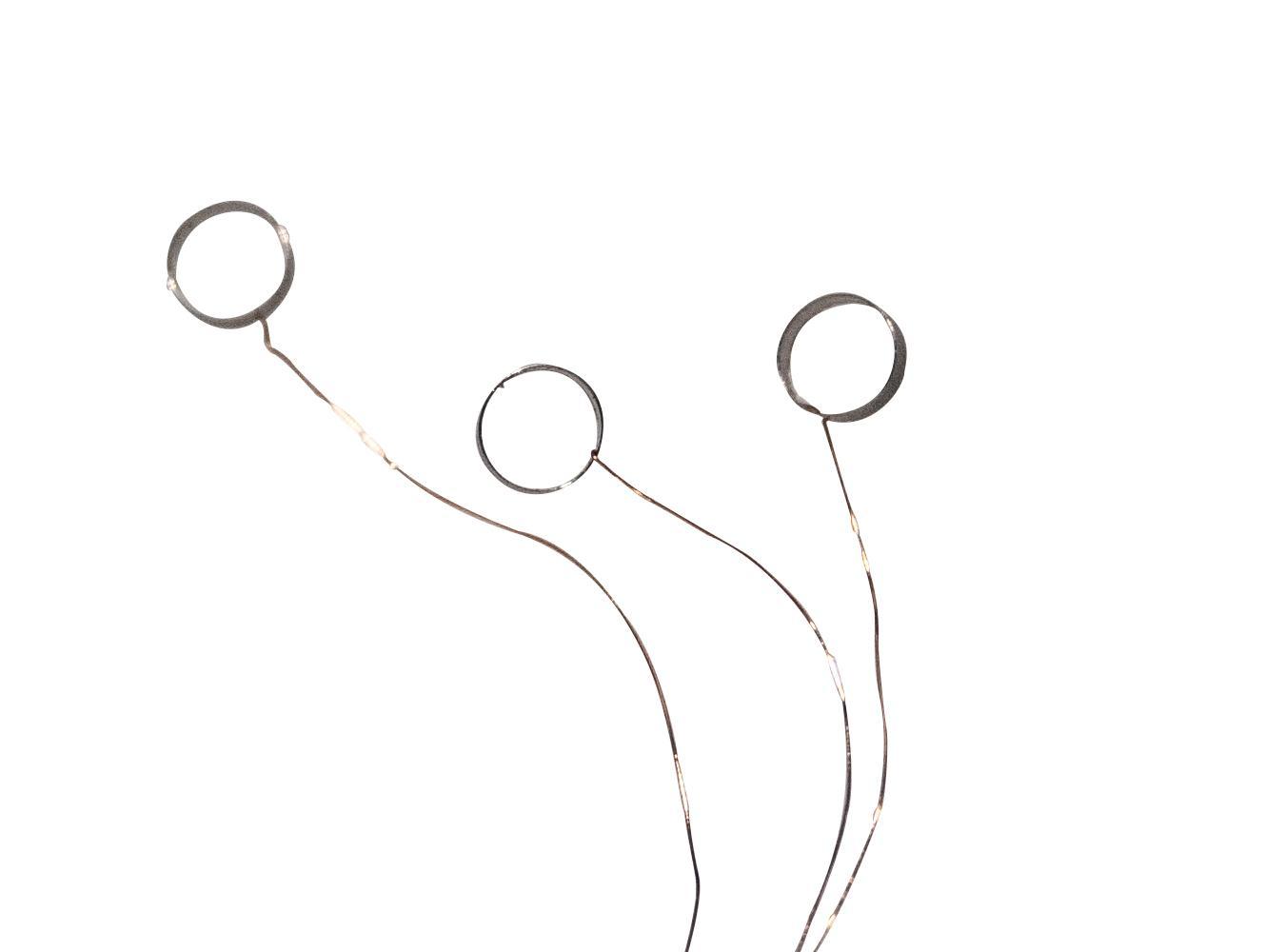

Active Catheter OEM&ODM

We make your catheter smart!

Smart Catheter application faces a key challenge in the need of bi-directional signals,current conduction and feedback loops between the proximal and distal ends. Through the integration of bi-directional feedback and control mechanisms, the Catheter is enabled to perform additional functions in real-time during treatment at the distal head. Yet the small space inherent in catheters adds to the complexity, making the integration of multiple sensors and functional modules a significant challenge.

Nowadays, most of the companies are still facing many problems such as backward manufacturing process and equipment, lack of talents with relevant experience, high assembly difficulty and high manufacturing cost. Based on many years of research and experience in minimally invasive interventional devices, Diagsensor is focusing on solving the pain of the industry, facing the opportunities and challenges of smart catheters, helping our customers to continue thier innovations through the development of key components and advanced process.

We are also the ideal choice for companies seeking partnerships in the co-development of components and finished devices. We offer integrated development and assembly manufacturing to complement and accelerate OEMs' ability to bring high-quality products to market quickly, while protecting and enhancing their intellectual property.

Please contact us to learn more about our capabilities, including:

Catheter

Welding

Assembly

Adhesive

Videos

Watch the video,Learn more about our products and services.Diagsensor is dedicated to the research and development of ultra-micro sensors for vital signs monitoring

Learn More