Precision laser processing to create a further future for medical manufacturing

Laser Manufacture Solution

Laser processing technology has made significant advancements in the medical industry, demonstrating vast market potential. With its high precision, efficiency, and versatility, laser processing meets the stringent demands of medical device manufacturing and healthcare services. As technology continues to evolve and applications expand, laser processing will play an increasingly vital role in the medical field, driving improvements in both the quality and standard of medical services.

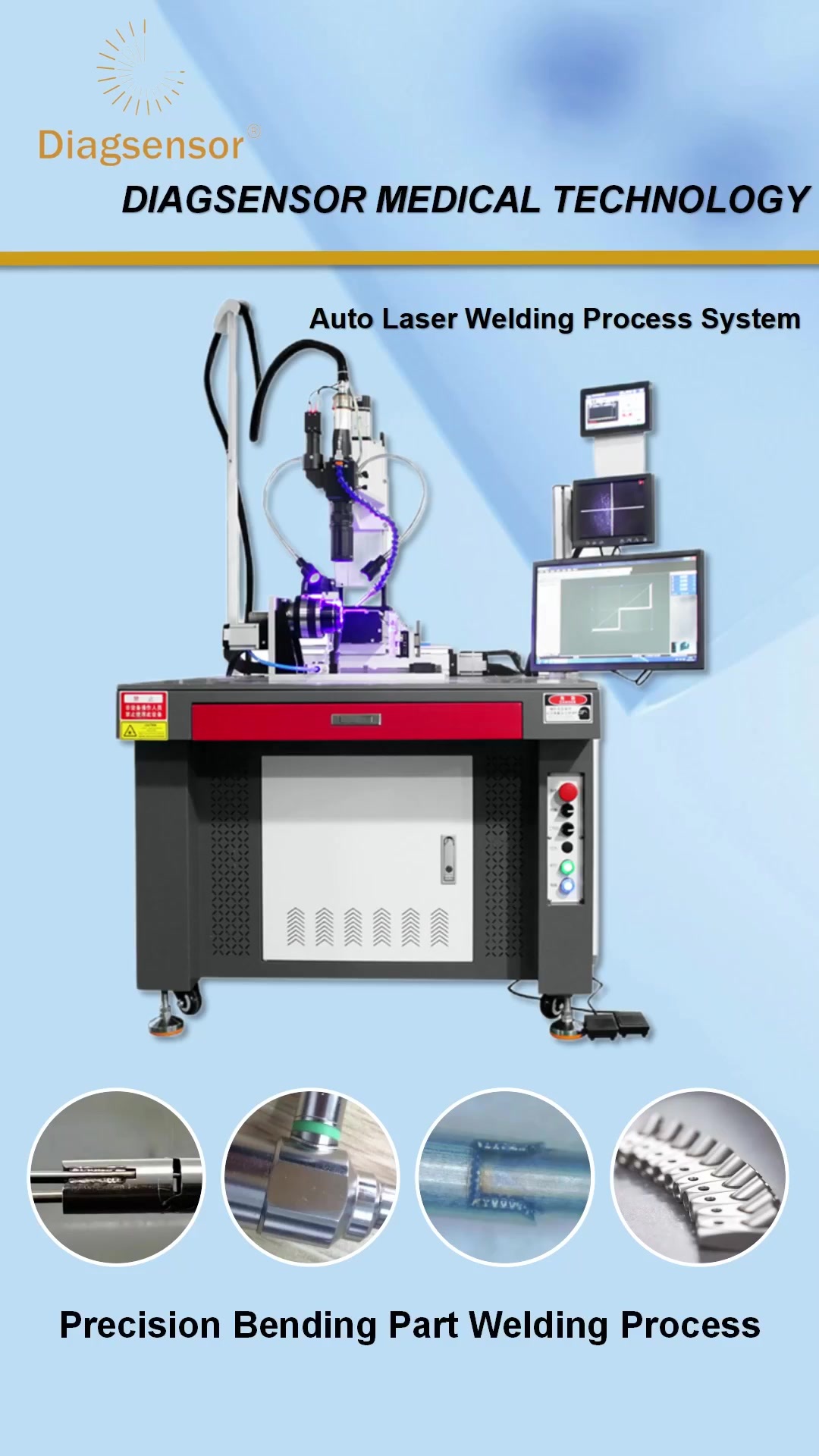

In Diagsensor, we have Interventional medical device laser micro - processing system. We use it for metal welding, insulator laser cutting, precision bending part welding, and cutting. Our laser welding processing system ensure high - quality manufacturing and offer highly customizable service.

Contact us for more laser manufacture solution.

Laser cutting

Hypotube \ bending section

Customize stainless steel Hypotube for endoscope bending section

Ultra-Fine Cutting Width: <20μm

High Precision: ≤±5μm

Excellent Edge Quality: Burr-Free & Smooth Finish

High Efficiency: One-Pass Penetration of Single-Sided Tube Wall & Continuous Automatic Feeding

Laser welding

Customized for endoscopic bending part welding and other precision welding

Equipped with imported Panasonic servo drives, ensuring repeat positioning accuracy of ±0.05mm.

The machine bed features high-precision ball screws for fast and accurate transmission.

Minimum laser weld spot: 0.3mm

Welding thickness range: 0.05–1mm

Laser power: 150W

Laser Striping

Wire diameter range: 0.04–3mm, supports precision laser stripping on both ends.

Laser processing offers precise control, high efficiency, clean cuts, minimal heat-affected zone, and aesthetically smooth welds.

With high precision and flexibility, the laser beam enables accurate stripping with a tolerance of ±0.05mm.

Using high-energy laser beams, the insulation layer is instantly melted and vaporized without damaging the conductor, achieving burr-free and deformation-free results.

Ideal for high-quality, high-precision wire insulation stripping applications.

Videos

Watch the video,Learn more about our products and services.Diagsensor is dedicated to the research and development of ultra-micro sensors for vital signs monitoring

Learn More