Making beauty more precise!

Medical Cosmetology

Providing Class III Medical-Grade Assembly and Manufacturing Solutions for the Medical Cosmetology Industry.

As medical cosmetology devices are now regulated under medical device standards, stricter requirements are imposed on manufacturing environments, quality control, and product safety. At the same time, precision and minimally invasive procedures have become key trends in medical cosmetology, demanding higher accuracy and consistency in device manufacturing.

With years of experience in Class III medical device production and delivery, Diagsensor ensures high-quality, high-stability solutions that meet rigorous industry standards. Our expertise in precision manufacturing enables us to develop medical cosmetology devices with exceptional accuracy, reliability, and micro-invasive capabilities. Through advanced manufacturing techniques, a comprehensive quality management system, and flexible customization services, we support the industry's technological advancement and drive its transformation, delivering safer and more efficient solutions for our customers.

We are the ideal partner for companies seeking a secure global supply chain or looking to manufacture and sell in China. With extensive experience in international business collaboration, Diagsensor Medical offers ultra-precision assembly, ISO 13485-certified factory services, and advanced medical sensor solutions to support your manufacturing and market entry needs.

Contact us to learn more about our capabilities, including:

🔹 OEM & ODM Solutions

🔹 Advanced Sensor Integration

🔹 Precision Manufacturing for Active Medical Devices

Catheter

· Laser Welding

· Tip Forming

· Drilling

· Flaring

· Scraping

· Forging

· Step Grinding

· Hydrophilic Coating

· Laser Marking

Welding

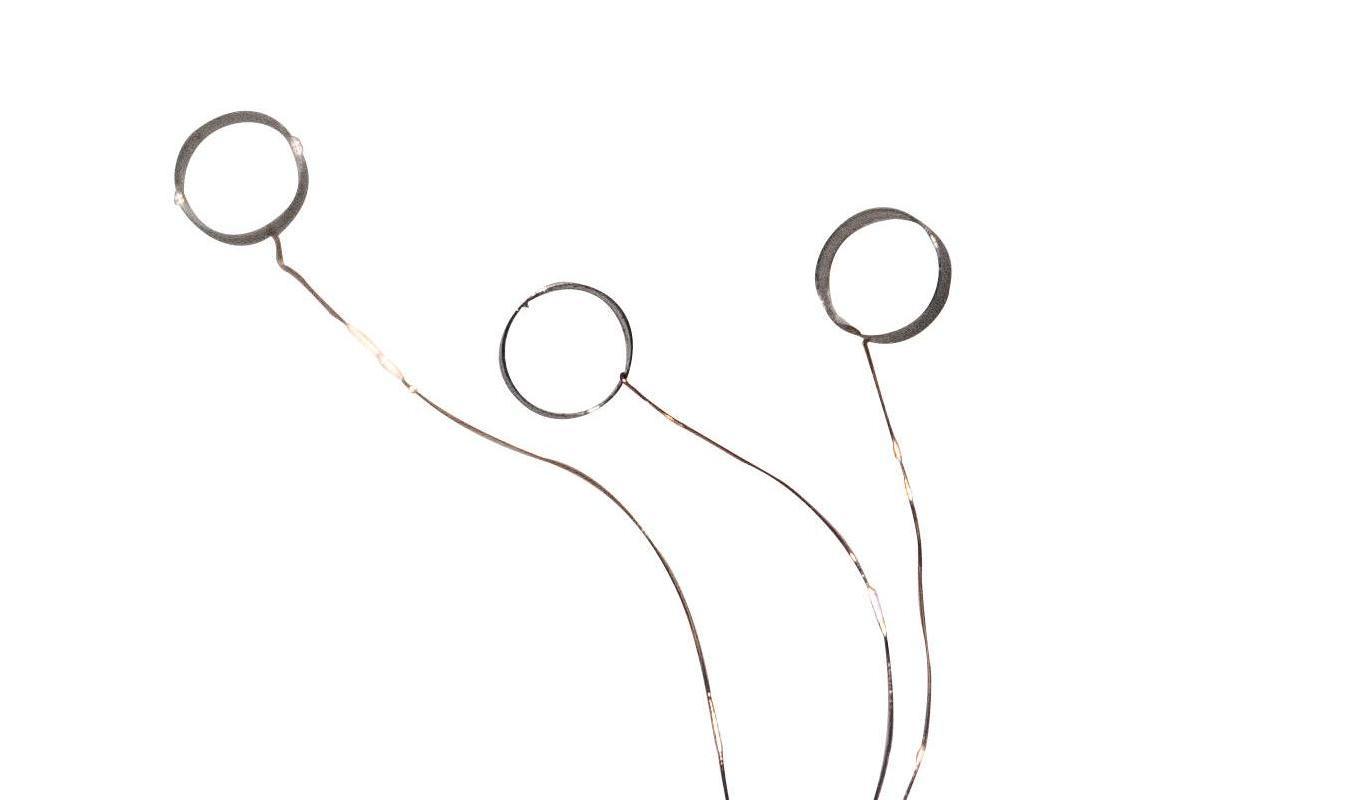

· MinOD0.009mm Wire Welding

· Dissimilar Metal Welding

· Electrode Ring and Wire Welding

· FPC Flexible Plate Welding

· Fusion Welding

· Tin Welding

· Laser Welding

· Ultrasonic Welding

Assembly

· Electrode Integration

· Bending Control Assembly Integration

· Multi-sensor Integration

· Multi-wire and Multi-cavity Tube Threading

· Catheter Reducing Nesting

· Hot Melt Forming

Adhesive

· Epoxy Glue Bonding

· Resin Glue Bonding

· UV Glue Bonding

· Silica Gel Preparation and Molding

· Heat Shrink Tube Processing

· Nickel-titanium Shape Assembly

· Thin Wire Coil (Prototyping)